- rifadrying@gmail.com

- +86 188 5253 7480

- No.12 Chuangye Road, Chenji Town Industrial Park, Yizeng, Jiangsu, China

The tower diameter and tower height of this production line are not limited by air sweeping arm, high production efficiency, low energy consumption, extended continuous production time, and basically there is no sticky wall phenomenon, good product quality, can be cleaned up, and improve the safety of production.

| Item No: | Y-LW Large continuous spray fluidized bed production line |

|---|

F-YPL Anti-Sticky Wall Spray Drying Small Granule Preparation Production Line

The successful development of the production line provides a possibility for the preparation of solid preparations by spray drying for the raw liquid of materials with strong hygroscopicity, prone to electrostatic wall sticking and thermal adhesion at the same time.

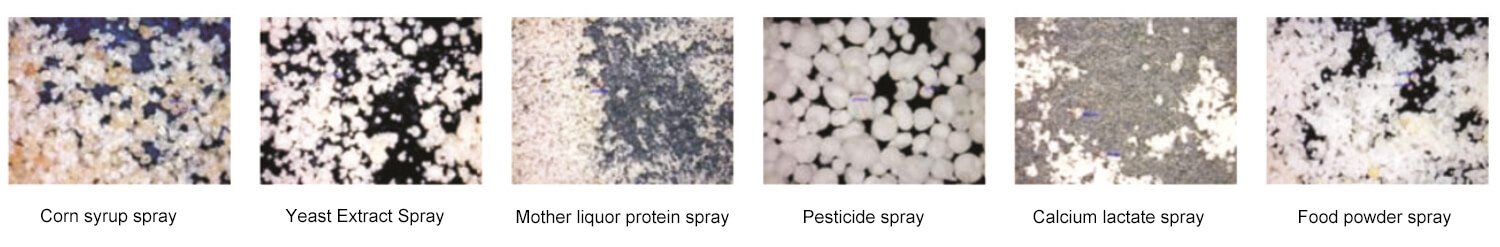

Application Material Refer:

Main features:

1. Reduce the material does not dry wet sticky wall, increase the tower height, tower diameter, air wall wind device.

2. Reduce the material electrostatic sticking wall, the production of material particles average 80-300 mesh, an average of 120 mesh, particle size is enough to avoid powder electrostatic sticking wall.

3. Reduce the material’s hot melting sticky wall, under the premise of ensuring the drying strength of the system, the temperature of the material can always be maintained at 50-80 degrees, to avoid hot melting sticky wall.

4. System sealing, less material loss, eliminating environmental pollution. The dryer operates under micro-negative pressure.

5. The key parts of the dryer are easy to replace, and the key control parameters can be adjusted to adjust the residence time of the materials to meet the needs of multi-species drying.

Large-scale continuous spray fluidized bed pills, granulation, drying, coating, internal heating fluidized bed, is Yangzhou Rifa’s characteristic technology.

Yangzhou Rifa Drying Engineering Co., Ltd. © Copyright 2022 by web building inc.

Please leave your message.