- rifadrying@gmail.com

- +86 188 5253 7480

- No.12 Chuangye Road, Chenji Town Industrial Park, Yizeng, Jiangsu, China

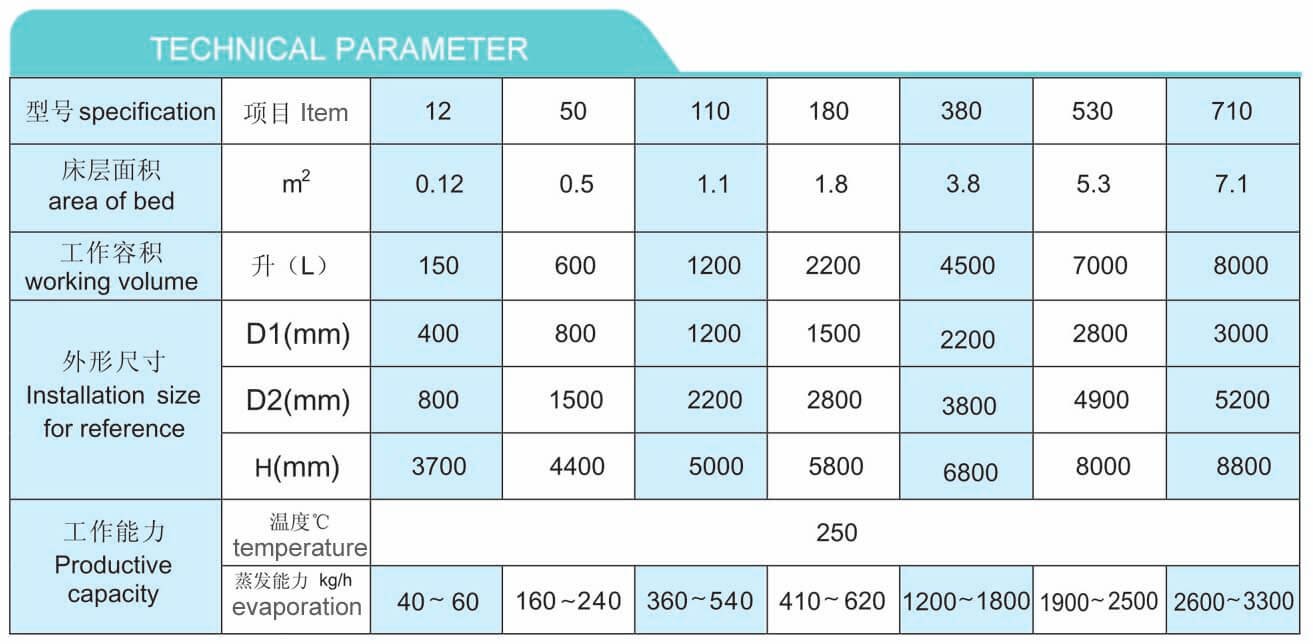

| Item No: | YLZ Continuous fluidized bed granulating and coating machine |

|---|---|

| Application: | The crystalline species can be powder, granule |

| Material liquid: | Can be wetting agent, concentrate, binder |

| Functions: | powder granulation, granule coating, granule coating |

Fluidized bed granulation coating machine, there are square fluidized bed and round fluidized bed. The use of hot air or mechanical force at the same time to make the fluidized bed “substrate” showing boiling or forced regular movement, the wetting agent, adhesive, packaging materials, or mother liquor in the appropriate direction uniformly sprayed into the agglomeration into a granule or laminar amplification can be achieved to achieve the effect of agglomeration granulation, coating granulation, granules or powder coating coating.

Equipment features:

1. The equipment has small volume and high evaporation intensity, which really realizes the big production of small equipment;

2. Various fluidized bed technologies have their own characteristics, according to the needs of the product can choose the appropriate fluidized bed.

3. The temperature of fluidized bed layer is low and relatively stable, suitable for the granulation of heat-sensitive materials.

The masterbatch (crystal seed, solid raw material) enters into the fluidized bed through the feeding system, and hot process air is passed into the bottom of the fluidized bed, so that the masterbatch forms a specific fluidization on the air-dividing mesh plate of the fluidized bed. The material particles form a specific gradient from inlet to outlet, through different forms of fluidized bed, to achieve continuous drying, granulation, coating function.

I.Drying Function

Fluidized bed from the inlet to the outlet, the use of wind plate design and through the bin structure, the realization of different positions, according to the specific drying characteristics of the material, the temperature from high to low, the moisture content of the material is gradually reduced, to achieve the most economic energy consumption and excellent quality of the product.

II.Granulation Function

Fluidized bed can realize continuous “agglomeration” granulation and continuous “coating” granulation to achieve a variety of product functions. Installed in the fluidized bed body through the spray gun into the liquid, in the masterbatch “coating” and “bonding” granulation, the smaller particles “coating”, such as particle size is not large enough, will be directly upstream to the exit of the cyclone separator (the exit of the cyclone separator). Cyclone separator at the outlet (or fall back directly after going up), and return to a specific part of the fluidized bed to reduce the chance of adhesion of small particles, large and medium-sized particles in the outlet of the fluidized bed through the mandatory wind selection, particles meeting the requirements of the particle size of the quantitative discharge, through the solids processing system (sieving, drying, cooling, pulverizing), to obtain the finished product, and particles other than the finished product will be returned to the fluidized bed as a masterbatch after processing, so as to realize the continuous granulation. Continuous granulation.

III. Coating function

The coating material is sprayed into the bed by a spray gun mounted on the bed, and the continuous drying structure design realizes continuous coating (cladding).

The above functions, together with specialized control systems, internal heating systems, and air intake systems, reach the latest heights of the current combination of technology and equipment, and can realize processes such as the following:

~Process for continuous drying of solid finished products and moisture-absorbing materials;

~Process for obtaining solid particles continuously from liquid materials (various degrees of solidity can be obtained);

~Processes for the continuous production of granules from powdered raw materials;

~Processes that allow for continuous coating of products with different release rates;

~Continuous spray crystallization process for liquid raw materials;

~Liquid raw material continuous pill making process;

Large-scale continuous spray fluidized bed pills, granulation, drying, coating, internal heating fluidized bed, is Yangzhou Rifa’s characteristic technology.

Yangzhou Rifa Drying Engineering Co., Ltd. © Copyright 2022 by web building inc.

Please leave your message.